An LVDT (Linear Variable Differential Transformer) core extension rod is a critical component that allows the sensor’s core to move freely while maintaining precise position measurement. It serves as a mechanical link between the LVDT core and the moving target, enabling accurate signal output even in applications where direct coupling to the core is not possible.

How Does a Core Extension Rod Help?

- Extends the Reach of the LVDT Core and Enables Remote or Hard-to-Reach Measurements

In many applications, the measured target is positioned away from the LVDT sensor. The extension rod bridges this gap, enabling the core to move with the target without repositioning the sensor. It also allows the sensor to be mounted in a protected location, shielding it from harsh environmental conditions while still accurately tracking movement at the measurement point.

- Supports Customization for Various Applications

Extension rods can be customized in length, diameter, and material to fit specific application needs. Whether for industrial automation, aerospace, or heavy machinery, the right extension rod can help to ensure optimal sensor performance.

Choosing the Right Core Extension Rod

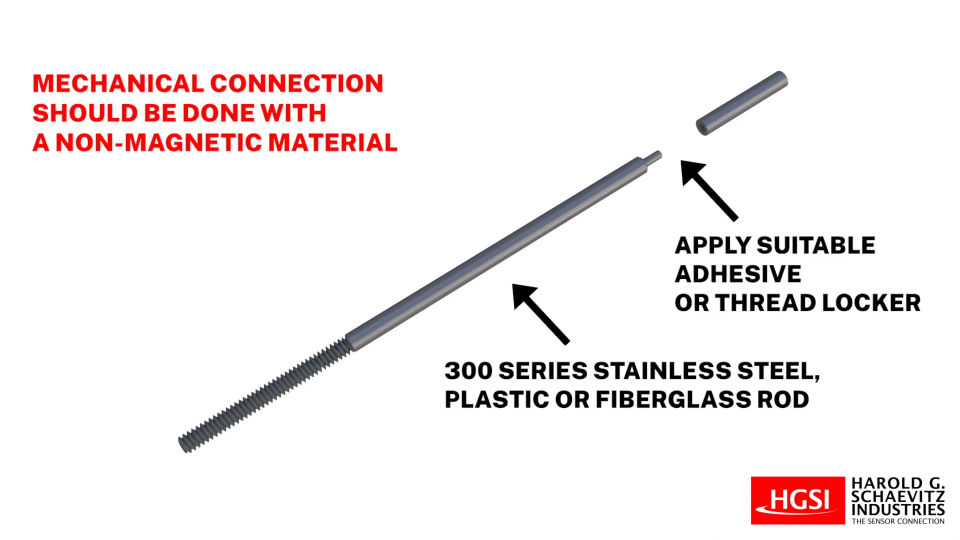

Material Matters – The mechanical connection to the core should be made using a non-magnetic material, preferably 300-series stainless steel, fiberglass, or a plastic rod, secured with a suitable adhesive or thread locker. Highly conductive materials such as aluminum or brass should be avoided, as they may generate eddy currents within the LVDT, leading to unacceptable measurement errors.

Proper Length and Diameter – The rod must be sized appropriately to maintain smooth operation and stability.

Would you like recommendations on LVDT core extension rods for your application? Contact us today!